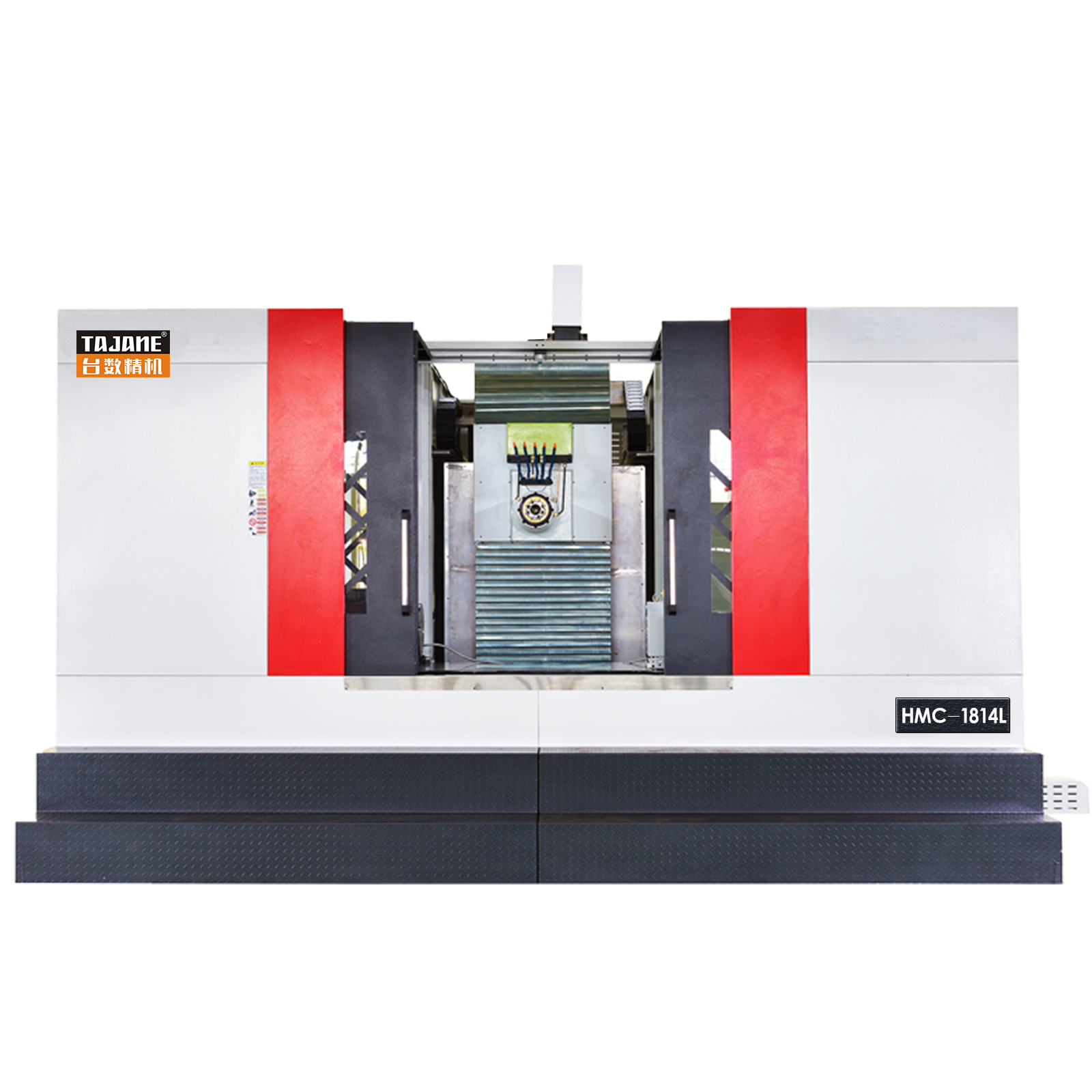

Horizontal Machining Center HMC-1814L

Qingdao Taizheng ofukula Machining Center ndiye kusankha kwanu kwabwino Machining mwatsatanetsatane. Gulu lathu la TAJANE vertical Machining Center limapangidwa mwapadera kuti lizitha kukonza magawo ovuta monga mbale, mbale, nkhungu ndi zipolopolo zazing'ono. Malo opangira makina osunthika amachita bwino kwambiri ntchito monga mphero, wotopetsa, kubowola, kugogoda ndi kudula ulusi.

Ubwino wapadera wa mankhwala athu ndi mkulu mwatsatanetsatane ndi kudya processing liwiro. Kupyolera muukadaulo wapamwamba komanso kapangidwe kake mosamala, malo opangira makina omwe timapereka amatha kumaliza zofunikira zamagulu aliwonse ovuta kwambiri mwatsatanetsatane. Kaya ndi ting'onoting'ono kapena mawonekedwe ovuta, zogulitsa zathu zitha kubwezeretsedwanso bwino ndikuwonetsetsa kuti gawo lililonse lakukonza ndilolondola.

Kugwiritsa ntchito mankhwala

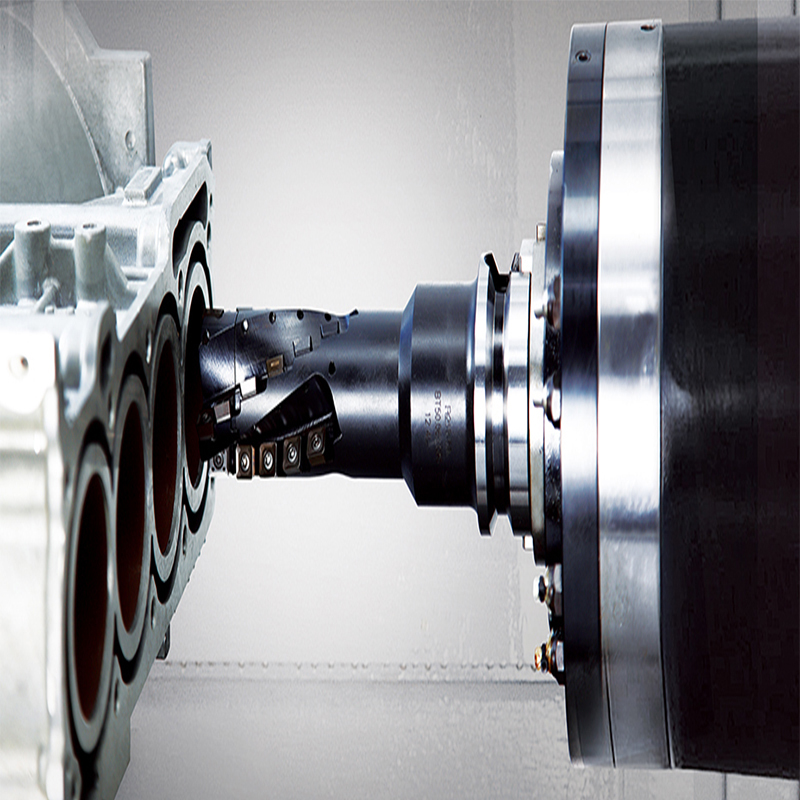

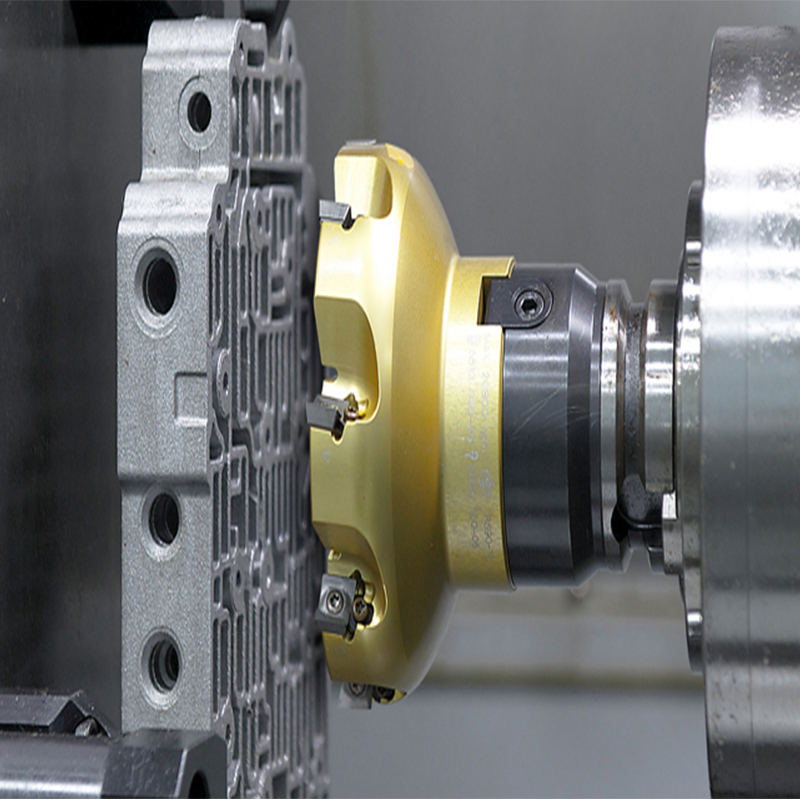

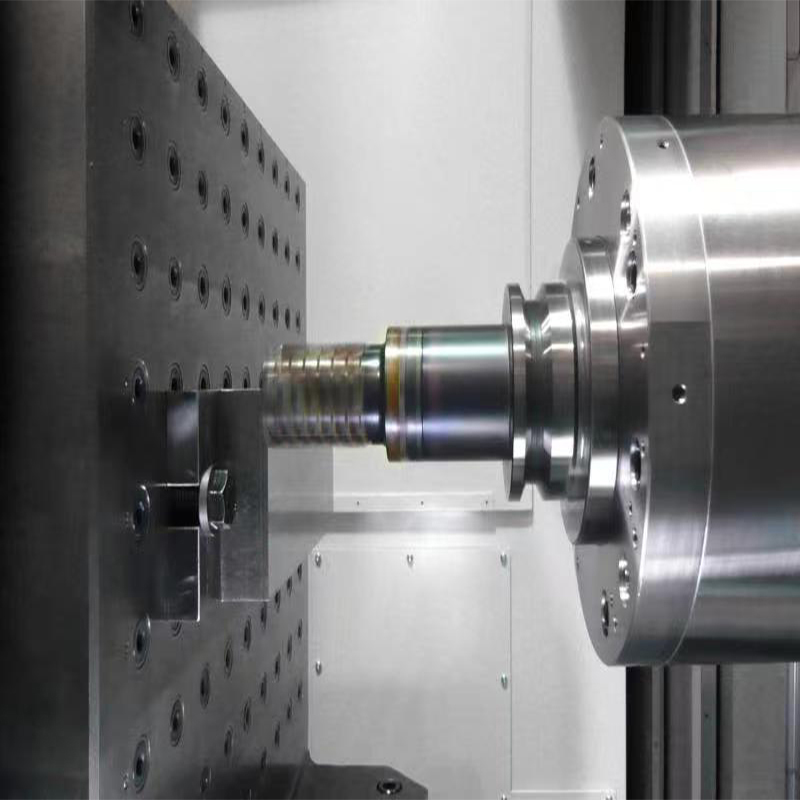

The ofukula Machining Center ndi kothandiza ndi yeniyeni zida processing kuti chimagwiritsidwa ntchito mbali processing m'madera osiyanasiyana. Sizingagwiritsidwe ntchito pokonza mbali zolondola za zinthu za 5G, komanso zimatha kukwaniritsa zofunikira za zipolopolo, zigawo zamagalimoto ndi mbali zosiyanasiyana za nkhungu. Makamaka zikafika pamakina a batch, malo opangira makina osunthika amapambana, kupangitsa kuti makina azigwira bwino ntchito, olondola kwambiri. Kuphatikiza apo, zida izi zitha kuzindikiranso kuthamanga kwambiri kwa magawo abokosi, kuwongolera magwiridwe antchito ndikuwongolera kulondola. Mwachidule, ofukula Machining pakati ndi zida zabwino kwambiri processing kuti amapereka mayankho abwino kwa mbali processing m'madera osiyanasiyana.

Horizontal Machining Center, yomwe imagwiritsidwa ntchito kwambiri pamagalimoto, zakuthambo, makina ambiri ndi mafakitale ena.

Horizontal Machining Center. Ambiri oyenera pokonza zikwapu zazikulu ndi zigawo zovuta mwatsatanetsatane

Yopingasa Machining pakati, oyenera Mipikisano ntchito pamwamba ndi Mipikisano ndondomeko processing zigawo

Horizontal Machining malo chimagwiritsidwa ntchito mbali zovuta. Kukonza pamwamba ndi dzenje.

Horizontal Machining malo chimagwiritsidwa ntchito mbali zovuta. Kukonza pamwamba ndi dzenje.

Njira yopangira zinthu

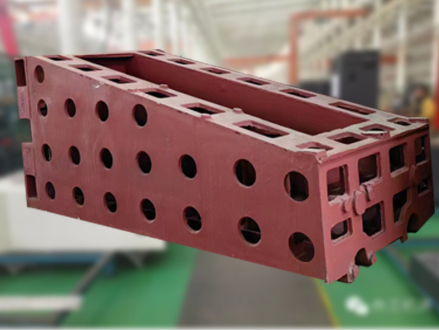

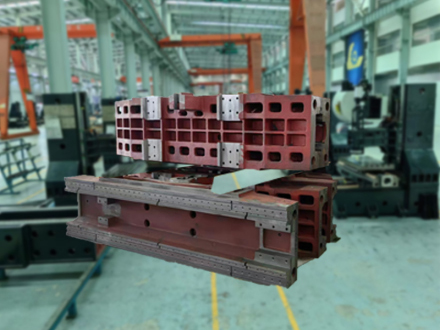

The castings of CNC VMC-855 ofukula Machining Center kutengera Meehanner kuponyera njira, kalasi TH300, amene ali ndi mphamvu mkulu ndi mkulu kuvala kukana. Malo opangira makinawo amatengera kapangidwe ka nthiti zamakhoma kawiri ngati nthiti mkati mwa kuponyera, ndipo bokosi la spindle limakhala ndi kapangidwe koyenera komanso koyenera, komwe kungapereke kulondola kwaukadaulo komanso kuchita bwino. Kuphatikiza apo, kulephera kwachilengedwe kwa bedi ndi mzati kumawongolera bwino kulondola kwa malo opangira makina. The worktable mtanda Wopanda ndi m'munsi kukwaniritsa zofunika kudula katundu ndi kuyenda mofulumira, kupereka owerenga ndi kothandiza kwambiri ndi khola processing zinachitikira.

CNC Horizontal Machining Center, kuponyera kumatenga njira yoponyera ya Meehanite, ndipo chizindikirocho ndi TH300.

Horizontal mphero makina, tebulo mtanda Wopanda ndi maziko, kukumana kudula katundu ndi kuyenda mofulumira

Horizontal mphero makina, mbali ya mkati mwa kuponyera utenga awiri mipanda gululi woboola pakati nthiti dongosolo.

Horizontal mphero makina, bedi ndi mizati amalephera mwachibadwa, kuwongolera mwatsatanetsatane pakati Machining.

Chopingasa Machining Center, wokometsedwa kamangidwe ka castings zisanu zazikulu, wololera masanjidwe

Zigawo za Boutique

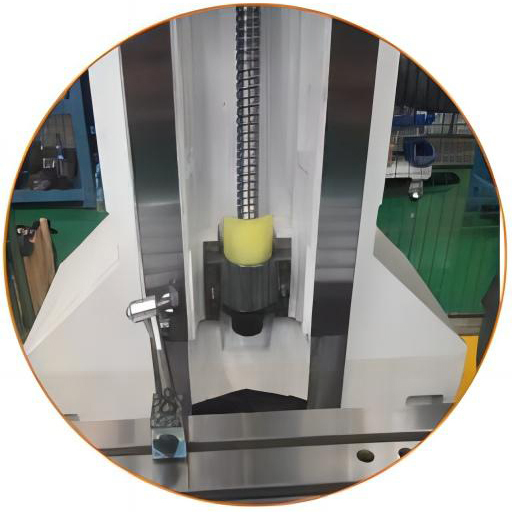

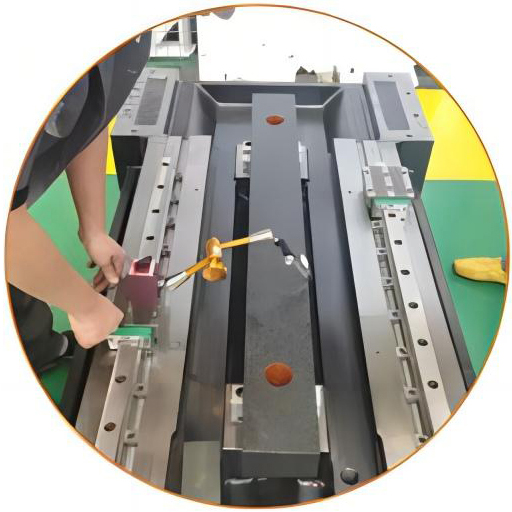

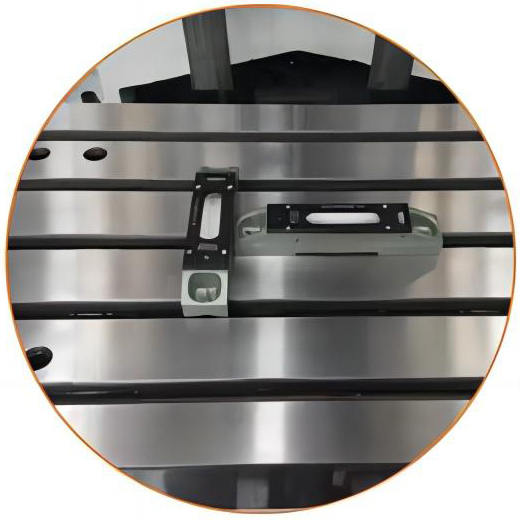

Njira yoyendetsera polojekiti yolondola

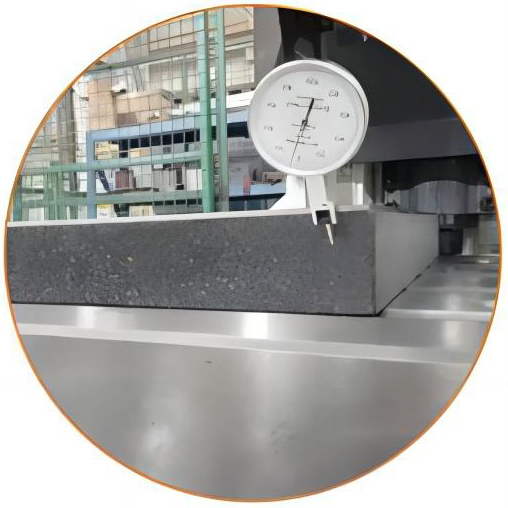

Mayeso Olondola a Workbench

Kuwunika kwa Gawo la Opto-Mechanical

Kuzindikira kwa Verticality

Kuzindikira kwa Parallelism

Kuwunika Kulondola kwa Mpando wa Nut

Kuzindikira Kupatuka kwa Engle

Konzani mtundu wa CNC system

TAJANE Horizontal Machining Center zida, malinga ndi zosowa za makasitomala, amapereka mitundu yosiyanasiyana ya makina a CNC kuti akwaniritse zosowa zosiyanasiyana zamakasitomala pamakina oyimirira, FANUC, SIEMENS, MITSUBISH, SYNTEC.

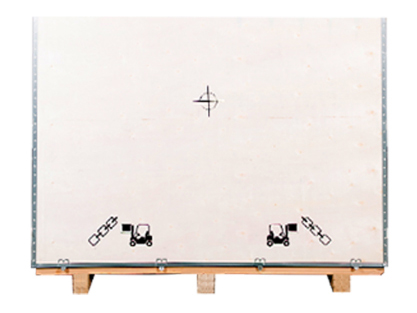

Zonyamula bwino, kuperekeza zoyendera

Kuyika kwathunthu kwamatabwa

Horizontal Machining Center HMC-1814L, phukusi lotsekedwa kwathunthu, kuperekeza zoyendera

Kuyika kwa vacuum m'bokosi

Horizontal Machining Center HMC-1814L, yokhala ndi zosunga zotchingira chinyezi mkati mwa bokosilo, yoyenera mayendedwe amtunda wautali.

Chotsani chizindikiro

Horizontal Machining Center HMC-1814L, yokhala ndi zolembera zomveka bwino mubokosi lopakira, kutsitsa ndi kutsitsa zithunzi, kulemera kwachitsanzo ndi kukula kwake, komanso kuzindikira kwakukulu.

matabwa olimba pansi bulaketi

Horizontal Machining Center HMC-1814L, pansi pa bokosi lonyamula katunduyo amapangidwa ndi matabwa olimba, omwe ndi olimba komanso osasunthika, ndikumangirira kuti atseke katunduyo.

| Zofotokozera | Mtengo wa HMC-1814L | |||

| Maulendo | X-Axis, Y-Axis, Z-Axis | X: 1050, Y: 850, Z: 950mm | ||

| Spindle Mphuno Ku Pallet | 150-1100 mm | |||

| Spindle Center to Pallet Surface | 90-940 mm | |||

| Table | Kukula kwa tebulo | 630x630mm | ||

| Nambala ya Workbench | 1(OP:2) | |||

| Kukonzekera kwa Workbench Surface | M16-125 mm | |||

| The Workbench Maximum Load | 1200kg | |||

| Gawo Laling'ono Kwambiri Lokhazikitsa | 1°(OP:0.001°) | |||

| Controller ndi Motor | 0IMF-s | 0IMF-a | 0IMF-s | |

| Spindle Motor | 15/18.5 kW (143.3Nm) | 22/26 kW (140Nm) | 15/18.5 kW (143.3Nm) | |

| X Axis Servo Motor | 3kW (36Nm) | 7kW (30Nm) | 3kW (36Nm) | |

| Y Axis Servo Motor | 3kW (36Nm)BS | 6kW (38Nm)BS | 3kW (36Nm)BS | |

| Z Axis Servo Motor | 3kW (36Nm) | 7kW (30Nm) | 3kW (36Nm) | |

| B Axis Servo Motor | 2.5kW (20Nm) | 3kW (12Nm) | 2.5kW (20Nm) | |

| Feed Rate | 0IMF-s | 0IMF-a | 0IMF-s | |

| X. Z Axis Rapid Feed Rate | 24m/mphindi | 24m/mphindi | 24m/mphindi | |

| Y Axis Rapid Feed Rate | 24m/mphindi | 24m/mphindi | 24m/mphindi | |

| XY Z Max.Cutting Feed Rate | 6m/mphindi | 6m/mphindi | 6m/mphindi | |

| ATC | Mtundu wa Arm (Chida mpaka Chida) | 30T (4.5 sec) | ||

| Chida cha Shank | Mtengo wa BT-50 | |||

| Max. Chida Diameter*Utali (moyandikana) | φ200*350mm(φ105*350mm) | |||

| Max. Kulemera kwa Chida | 15kg pa | |||

| Kulondola Kwamakina | Positioning Accuracy (JIS) | ± 0.005mm / 300mm | ||

| Kubwereza Poitioning Kulondola (JIS) | ± 0.003mm | |||

| Ena | Pafupifupi Kulemera kwake | A: 15500kg / B: 17000kg | ||

| Kuyeza kwa Pansi | A: 6000*4600*3800mm B: 6500*4600*3800mm | |||

Standard Chalk

● Spindle ndi servo motor load chiwonetsero

● Kuteteza kwa spindle ndi servo overload

●Kugogoda mosasunthika

● Chophimba chotchinga chotchinga chonse

● Wilo lamanja lamagetsi

● zida zowunikira

● Chotengera cha Double spiral chip

●Automatic lubrication system

● Thermostat yamagetsi yamagetsi

● Spindle chida chozizirirapo

● Mawonekedwe a RS232

●Mfuti za Airsoft

● Makina otsuka taper

●Zida

Zosankha Zosankha

● Chipangizo chodziwira cholamulira cha ma axis atatu

●Njira yoyezera zinthu

●Njira yoyezera zida

●Zizilira mkati mwa spindle

● tebulo lozungulira la CNC

●Chain chip conveyor

●Chida cha kutalika kwa chida ndi chopeza m'mphepete

● Cholekanitsa madzi

●Chida chozizirira madzi cha spindle

● Kugwiritsa ntchito intaneti