CNC Machining Center: maziko aukadaulo wapamwamba wopanga

I. Chiyambi

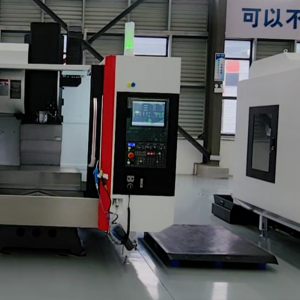

M'makampani opanga zinthu zamakono,CNC Machining Center, monga chida chachikulu cha makina a CNC, chimagwira ntchito yofunika kwambiri. Zimaphatikiza ukadaulo wapamwamba ndi ntchito kuti zikwaniritse magwiridwe antchito abwino komanso olondola komanso kupereka magawo apamwamba ndi zinthu zamafakitale osiyanasiyana. Nkhaniyi tikambirana mozama makhalidwe, processing mfundo, ubwino ndi zofooka zaCNC Machining Center, ndikuwunika momwe amagwiritsira ntchito komanso chitukuko chamtsogolo pamakampani opanga zinthu.

II. Makhalidwe a CNC Machining Center

CNC Machining Center amapangidwa pamaziko aCNC makina mphero, koma ili ndi mawonekedwe apadera omwe amasiyanitsa ndi makina a CNC mphero. Chimodzi mwazinthu zofunika kwambiri ndi laibulale yake ya mpeni komanso kuthekera kosintha mipeni. Kupyolera mu chipangizo chosinthira chida ichi, malo opangira makina amatha kusintha zida zosiyanasiyana pakupanga kumodzi, kuti amalize ntchito zosiyanasiyana zovuta kupanga. Mbali imeneyi kwambiri bwino processing Mwachangu ndi kusinthasintha, amachepetsa chiwerengero cha clamping wa workpieces, ndi kuchepetsa kuthekera Machining zolakwika.

Kuphatikiza apo, malo opangira makina a CNC nthawi zambiri amakhala ndi makina owongolera olondola kwambiri komanso ukadaulo wapamwamba woyendetsa, womwe ungatsimikizire kulondola komanso kukhazikika kwa makina. Itha kukonza zida zamitundu yosiyanasiyana komanso kukula kwake, kaya ndi geometry yosavuta kapena malo ovuta, omwe amatha kuthana nawo mosavuta. Pa nthawi yomweyo, pakati Machining alinso amphamvu kudula luso ndi mkulu-liwiro processing ntchito, amene angathe kukwaniritsa zofunikira za mafakitale osiyanasiyana kwa processing dzuwa ndi khalidwe.

III. Mfundo za kutsimikiza kwa njira zopangira

M'kati mwa CNC Machining Center, ndikofunikira kwambiri kudziwa njira yosinthira. Zotsatirazi ndi mfundo zomwe nthawi zambiri zimatsatiridwa:

1. Kuwonetsetsa kulondola ndi kuuma kwa pamwamba pa chogwirira ntchito: Mapangidwe a makina opangira makina ayenera kuganizira kaye momwe angatsimikizire zolondola komanso zovuta zapamtunda zomwe zimapangidwira. Izi zimafuna kuganiziridwa mozama za zinthu monga kusankha zida, kudula magawo ndi kutsata makina. Kupyolera mu kukonzekera koyenera, zolakwika zokonza zikhoza kuchepetsedwa ndipo ubwino wa workpieces ukhoza kusinthidwa.

2. Kufupikitsa njira yopangira: Pofuna kupititsa patsogolo kayendetsedwe ka kayendetsedwe kake, njira yowonongeka iyenera kufupikitsidwa momwe zingathere ndipo nthawi yopanda kanthu iyenera kuchepetsedwa. Izi zitha kutheka mwa kukhathamiritsa njira yachida ndikukonza njira yoyendetsera bwino. Pa nthawi yomweyo, kupewa zosafunika mobwerezabwereza processing ndi njira zozungulira kupulumutsa processing nthawi ndi mphamvu.

3. Mawerengedwe osavuta a manambala: Kutsimikiza kwa njira yopangira kuyenera kufewetsa ntchito yowerengera manambala momwe mungathere pakukonza ndi kugwira ntchito. Izi zitha kutheka posankha njira yoyenera yolumikizirana ndikugwiritsa ntchito njira yokhazikika ya zida. Kufewetsa pulogalamu yokonza sikungowonjezera luso la mapulogalamu, komanso kuchepetsa kuthekera kwa zolakwika za pulogalamu.

4. Kugwiritsa ntchito ma subroutines: Pamapulogalamu ena omwe agwiritsidwanso ntchito, magawo ang'onoang'ono ayenera kugwiritsidwa ntchito pokonza mapulogalamu. Izi zitha kuchepetsa utali wa pulogalamuyo ndikuwongolera bwino komanso kuwerengeka kwa mapulogalamu. Panthawi imodzimodziyo, subroutine imathanso kusinthidwa mosavuta ndikusungidwa kuti ikhale yosinthika komanso yosinthikanso pulogalamuyo.

IV. Ubwino waCNC Machining Center

CNC Machining Centerali ndi zabwino zambiri, zomwe zimapangitsa kuti azigwiritsidwa ntchito kwambiri m'makampani opanga zamakono:

1. Chepetsani kuchuluka kwa zida zogwiritsira ntchito: Chifukwa makina opangira makina amatha kukwaniritsa ntchito zosiyanasiyana pogwiritsa ntchito makina osinthika, safunikira zida zambiri zovuta pokonza magawo omwe ali ndi mawonekedwe ovuta. Pokhapokha posintha pulogalamu yokonza magawo, kukonza magawo amitundu yosiyanasiyana ndi makulidwe amatha kuzindikirika, zomwe zimachepetsa kwambiri kuchuluka ndi mtengo wa zida. Izi ndizopindulitsa kwambiri pa chitukuko ndi kusinthidwa kwa zinthu zatsopano, ndipo zimatha kuyankha mwamsanga pakufuna kwa msika.

2. Ubwino wokhazikika wokhazikika: Malo opangira makina ali ndi njira yoyendetsera bwino kwambiri komanso luso lapamwamba loyendetsa galimoto, lomwe lingathe kutsimikizira khalidwe lokhazikika la processing. Ili ndi kulondola kwapamwamba komanso kubwerezabwereza, zomwe zimatha kukwaniritsa zofunikira zamafakitale olondola kwambiri monga ndege. Kuphatikiza apo, njira yopangira malo opangira zinthu imakhala yosasunthika komanso yosakhudzidwa ndi zinthu zaumunthu, zomwe zimathandiza kuonetsetsa kuti zinthu zili bwino.

3. Kupanga kwakukulu: Pankhani yamitundu yambiri ndi yaing'ono yopanga ma volume, theCNC Machining Centerangapereke kusewera kwathunthu kwa ubwino wake kothandiza. Mwa kuchepetsa nthawi yokonzekera kupanga, kusintha kwa chida cha makina ndi kuyang'anira ndondomeko, ndikugwiritsa ntchito njira yabwino kwambiri yochepetsera kuchepetsa nthawi yodula, malo opangira makina amatha kusintha kwambiri kupanga. Nthawi yomweyo, kuthekera kwake kosinthika kumatha kukwaniritsa zosowa za makasitomala osiyanasiyana ndikuwongolera mpikisano wamsika wamabizinesi.

4. Malo ovuta omwe angathe kukonzedwa:CNC Machining Centerimatha kukonza zinthu zovuta zomwe zimakhala zovuta kuzikonza ndi njira zodziwika bwino, monga malo opindika, mawonekedwe apadera, ndi zina zambiri. Izi zimapereka malo owoneka bwino komanso mwayi wopanga makampani opanga zinthu, komanso zimathandizira kulimbikitsa luso lazogulitsa ndi kukweza.

V. Kuipa kwa CNC Machining Center

Ngakhale malo opangira makina a CNC ali ndi zabwino zambiri, palinso zolakwika zina zomwe ziyenera kutsatiridwa:

1. Mtengo wa zida zamakina ndi okwera mtengo: mtengo wa zida zaCNC Machining Centerndizokwera kwambiri, zomwe zitha kukhala zolemetsa zambiri zamabizinesi ena ang'onoang'ono ndi apakatikati. Kuphatikiza apo, ndalama zake zokonzetsera ndi kukonza ndizokwera kwambiri, zomwe zimafunikira akatswiri amisiri kuti azigwira ntchito ndikusamalira.

2. Amafuna ogwira ntchito yokonza kuti akhale ndi mlingo wapamwamba: Popeza CNC Machining Center ndi apamwamba-chatekinolojeCNC makina chida, kukonza ndi kukonza kwake kumafuna chidziwitso chaukadaulo ndi luso. Ogwira ntchito yosamalira ayenera kudziwa bwino kamangidwe, mfundo ndi kayendetsedwe ka makina a makina, ndikutha kuweruza mwachangu komanso molondola ndikuthetsa zolakwika. Kwa mabizinesi, ndikofunikira kuphunzitsa kapena kulemba anthu ogwira ntchito zapamwamba, zomwe zimawonjezera mtengo wabizinesi.

VI. Kugwiritsa ntchito CNC Machining Center

CNC Machining Center chimagwiritsidwa ntchito m'mafakitale osiyanasiyana. Zotsatirazi ndi zina zomwe zimagwiritsidwa ntchito nthawi zambiri:

1. Malo oyendetsa ndege: M'munda wamlengalenga, kulondola ndi khalidwe la zigawo zake ndizokwera kwambiri. TheCNC Machining Centerimatha kukonza magawo osiyanasiyana amitundu yovuta, monga masamba a injini ya ndege, zida zamapangidwe a ndege, ndi zina zambiri, kuti zikwaniritse zofunikira kwambiri pazamlengalenga.

2. Makampani opanga magalimoto: Makampani opanga magalimoto ndi amodzi mwamagawo ofunikira opangira makina a CNC. CNC Machining Center angagwiritsidwe ntchito pokonza mbali zofunika monga galimoto yamphamvu yamphamvu chipika, silinda mutu ndi crankshaft, komanso mbali zazikulu monga galimoto galimoto ndi chassis. Kutha kwake koyenera komanso kolondola kumatha kupititsa patsogolo luso komanso luso la kupanga magalimoto.

3. Makampani opanga nkhungu: Kupanga nkhungu ndi gawo lina lofunikira la ntchitoCNC Machining Center. Kulondola ndi khalidwe la nkhungu zimakhudza mwachindunji khalidwe ndi kupanga bwino kwa mankhwala. CNC Machining Center imatha kukonza mawonekedwe osiyanasiyana ovuta a nkhungu, monga nkhungu za jakisoni, zowola-ponyera, zopindika, ndi zina zambiri, kupereka chithandizo chodalirika chamakampani opanga nkhungu.

4. Makampani opanga zamagetsi: M'makampani opanga zamagetsi,CNC Machining Centerangagwiritsidwe ntchito pokonza zigawo zosiyanasiyana zamagetsi, monga matabwa ozungulira osindikizidwa, zipolopolo za foni yam'manja, zipolopolo zamakompyuta, ndi zina zotero. Mphamvu yake yolondola kwambiri komanso yothamanga kwambiri imatha kukwaniritsa zofunikira zamakampani opanga zamagetsi kuti zikhale zolondola komanso zamtundu wa zigawo.

5. Makampani opanga zida zamankhwala: Makampani opanga zida zamankhwala alinso ndi zofunika kwambiri pakulondola komanso mtundu wa magawo. CNC Machining Center imatha kukonza zida zosiyanasiyana zachipatala, monga zida zopangira opaleshoni, zipolopolo za zida zamankhwala, ndi zina zambiri, ndikupereka njira yofunika yopangira makampani azachipatala.

Zisanu ndi ziwiri. Chitukuko Chamtsogolo chaCNC Machining Center

Ndi kupita patsogolo kosalekeza kwa sayansi ndi ukadaulo komanso chitukuko chopitilirabe chamakampani opanga zinthu, malo opangira makina a CNC abweretsanso mwayi watsopano wachitukuko ndi zovuta. Nazi zina zomwe zikuchitika m'tsogolomu:

1. Wanzeru: TsogoloCNC Machining Centeradzakhala anzeru kwambiri, ndi kuphunzira paokha, kusintha kusintha ndi ntchito zina. Kudzera kugwiritsa ntchito luso yokumba nzeru, pakati Machining akhoza basi konza magawo Machining ndi njira chida malinga ndi makhalidwe ndi zofunika processing wa workpiece, ndi kusintha Mwachangu processing ndi khalidwe.

2. Kuthamanga kwakukulu: Ndi kupititsa patsogolo kosalekeza kwa zofunikira za makampani opanga zinthu kuti apange bwino, chitukuko chapamwamba cha malo opangira makina a CNC chidzakhala chosapeŵeka. M'tsogolomu, malo opangira makina adzakhala ndi liwiro lalikulu la spindle, liwiro la chakudya chofulumira komanso kuthamanga kwakukulu kuti akwaniritse ntchito zopangira makina.

3. Kuphatikiza: Kuti akwaniritse zosowa zamakampani opanga zinthu zambiri zogwirira ntchito, aCNC Machining Centeridzakula molunjika ku kompositi. Malo opangira makina am'tsogolo adzaphatikiza ntchito zosiyanasiyana zogwirira ntchito, monga kutembenuza, mphero, kubowola, kugogoda, ndi zina zotero, kuti akwaniritse zolinga zambiri makina amodzi ndikuwongolera kuchuluka kwa magwiritsidwe ntchito ndi kupanga bwino kwa zida.

4. Greening: Ndi mosalekeza kuwongola wa kuzindikira zachilengedwe, chitukuko chobiriwira chaCNC Machining Centeridzakhalanso njira yofunika kwambiri m'tsogolomu. Malo opangira mtsogolo adzatengera matekinoloje opulumutsa mphamvu komanso okonda zachilengedwe komanso zida zochepetsera kugwiritsa ntchito mphamvu komanso kuwononga chilengedwe.

5. Networked: Ndi chitukuko chosalekeza chaukadaulo wazidziwitso, chitukuko cha intaneti chaCNC Machining Centeridzakhalanso njira yofunika kwambiri m'tsogolomu. Malo opangira makina amtsogolo adzatha kugwirizanitsa ndi kuyanjana ndi zipangizo zina ndi machitidwe kudzera pa intaneti, kuzindikira kuwunika kwakutali, kufufuza zolakwika, kufalitsa mapulogalamu ndi ntchito zina, ndikuwongolera bwino ndi nzeru za kayendetsedwe ka kupanga.

VIII. Mapeto

Monga patsogoloCNC makina chida, CNC Machining Center imagwira ntchito yofunika kwambiri pakupanga zamakono. Ili ndi mawonekedwe apadera ndi maubwino, imatha kuzindikira magwiridwe antchito abwino komanso olondola, komanso imapereka magawo apamwamba ndi zinthu zamafakitale osiyanasiyana. Ndi kupita patsogolo kosalekeza kwa sayansi ndi ukadaulo komanso kukula kosalekeza kwamakampani opanga zinthu, malo opangira makina a CNC nawonso apitiliza kupanga zatsopano ndikukweza, kupereka chithandizo champhamvu chaukadaulo pakukula kwamakampani opanga zinthu. Mtsogolomu,CNC Machining Centeridzakulitsa njira yanzeru, kuthamanga kwambiri, kuphatikizika, kubiriwira ndi maukonde, kupanga zopereka zazikulu pakusintha ndi kukweza ndi chitukuko chapamwamba chamakampani opanga zinthu.

Millingmachine@tajane.comIyi ndiye adilesi yanga yaimelo. Ngati mukufuna, mutha kunditumizira imelo. Ndikuyembekezera kalata yanu ku China.