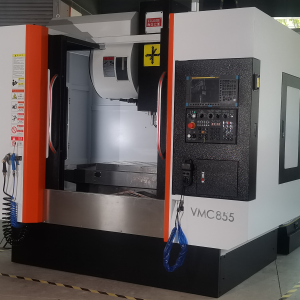

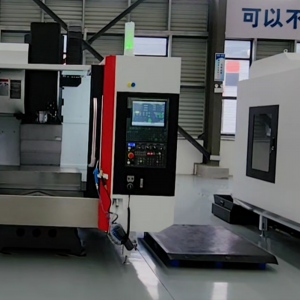

Masiku ano makampani opanga zinthu.CNC makina mpheroakhala akugwiritsidwa ntchito kwambiri chifukwa chaubwino wawo waukulu monga kulondola kwambiri, kuchita bwino kwambiri, komanso kuchuluka kwazinthu zokha. Komabe, kuti mugwiritse ntchito bwino makina a CNC mphero ndikukwaniritsa kukonza kwapamwamba komanso kothandiza, kusankha zida zodulira ndikofunikira. Monga chigawo chachikulu mwachindunji nawo kudula, kusankha wololera zida kudula mwachindunji zimakhudza khalidwe ndi kupanga dzuwa la chomaliza. Kutengera izi, nkhaniyi ifotokozanso zofunikira pakusankha zidaCNC makina mphero.

1, Zofunika kudula zida mu CNC mphero makina processing

Chifukwa cha kulondola kwake, kuthamanga kwambiri, komanso kuchuluka kwa automation,CNC makina mpheroaika patsogolo zofunika zokhwima za zida zomwe zimagwiritsidwa ntchito. Pofuna kuonetsetsa kuti makinawa ali abwino komanso kuwongolera bwino, zida zamakina a CNC ziyenera kukhala ndi izi:

(1) Kudalirika ndi Kukhazikika

Choyamba, zida zodulira ziyenera kukhala zodalirika komanso zolimba. Mu mosalekeza Machining ndondomeko yaCNC makina mphero, chidacho chiyenera kupirira mphamvu zodula kwambiri ndi zotentha zotentha kwa nthawi yaitali. Ngati kudalirika kwa chida sikukwanira kapena kukhazikika kwake kumakhala kochepa, n'zosavuta kukumana ndi mavuto monga kuvala msanga ndi kugwa kwa m'mphepete, zomwe sizimangokhudza khalidwe la makina komanso zimapangitsa kuti pakhale kusintha kwa zida kawirikawiri, kumawonjezera nthawi yopangira, komanso kuchepetsa kupanga. Chifukwa chake, kusankha zida zokhala ndi kukana kovala bwino, kukana kukhudzidwa, komanso kukhazikika kwamafuta, komanso kapangidwe kake ka zida, ndiye chinsinsi chothandizira kudalirika kwa zida komanso kulimba.

(2) Kukhazikika ndi mphamvu

Kuti akwaniritse zofunikira zakuya kwakukulu ndi kudyetsa mofulumira panthawi yokonza zovuta, chidacho chiyenera kukhala ndi kuuma bwino ndi mphamvu. Kuzama kwakukulu ndi kudyetsa mwachangu kungapangitse chida kupirira mphamvu zazikulu zodulira. Ngati kuuma kwa chida sikukwanira, kumakhala kosavuta kusinthika, komwe kumakhudza kulondola kwa makina; Kupanda mphamvu zokwanira kungayambitse kusweka kwa zida ndikuyambitsa ngozi zachitetezo. Choncho, popanga zida ndi kupanga, miyeso monga kukhathamiritsa mawonekedwe a geometric chida ndikusankha zida zamphamvu kwambiri ziyenera kutengedwa kuti zitsimikizire kuti chidacho chili ndi kuuma ndi mphamvu zokwanira.

(3) Kuphwanya chip ndikuchotsa magwiridwe antchito

Kuphwanya bwino kwa chip ndikuchotsa magwiridwe antchito ndikofunikira pakuwonetsetsa kuti zida zamakina zikuyenda bwino. M'kati mwaKusintha kwa CNC, kubadwa kosalekeza ndi kudzikundikira tchipisi. Ngati chidacho sichingathe kuthyola ndikuchotsa tchipisi, chimapangitsa tchipisi kuti chizikulungitsa chida kapena ntchito, zomwe zimakhudza kukhazikika kwa njira yodulira komanso kuwononga chida ndi chida cha makina. Kuti mukwaniritse bwino kuchotsedwa kwa chip, magawo a mawonekedwe odulira, mbali yakutsogolo, ndi mbali yakumbuyo ya chida ayenera kupangidwa mosamala. Nthawi yomweyo, kusankha koyenera kwa magawo odulira ndikugwiritsa ntchito madzi odulira kungathandizenso kusintha kusintha kwa chip.

(4) Kuyika kosavuta ndikusintha

Kusavuta kwa kukhazikitsa ndikusintha zida ndikofunikira kwambiri pakuwongolera magwiridwe antchito ndikuwonetsetsa kuti makina akulondola. Mu CNC mphero makina processing, chifukwa pafupipafupi chida m'malo ndi kusintha malo chida, ngati chida unsembe ndi kusintha ndondomeko ndi zovuta ndi zovuta, izo zitaya nthawi yambiri. Chifukwa chake, zida zodulira ndi zida zokhala ndi mawonekedwe osavuta, kukhazikitsa kodalirika ndikuyika, ndikusintha koyenera kuyenera kusankhidwa kuti muchepetse kusintha kwa zida ndi nthawi yosinthira, ndikuwongolera kuchuluka kwa makina ogwiritsira ntchito.

(5) Zida zapamwamba kwambiri zodulira zida

Kusankha zida zapamwamba kwambiri ndiye maziko owongolera magwiridwe antchito a zida. Pakadali pano, zida zomwe zimagwiritsidwa ntchito kwambiriCNC makina mpherozimaphatikizapo zitsulo zothamanga kwambiri, ma aloyi olimba, zotayira zokutira, zoumba, cubic boron nitride, ndi diamondi. Zida zosiyanasiyana za zida zimakhala ndi machitidwe osiyanasiyana, ndipo zida zoyenera ziyenera kusankhidwa malinga ndi zinthu monga zinthu za workpiece, teknoloji yokonza, ndi kudula. Mwachitsanzo, zida zodulira zitsulo zothamanga kwambiri zimakhala ndi kulimba komanso kugaya bwino, zomwe zimawapanga kukhala oyenera kukonza magawo owoneka bwino komanso otsika kwambiri; Zida zodulira zolimba zolimba zimakhala ndi kuuma kwakukulu komanso kukana kwabwino kovala, kuzipangitsa kuti zikhale zoyenera kudula mwachangu komanso kukonza movutikira; Zida zodulira zokutira zimapititsa patsogolo magwiridwe antchito awo pophimba pamwamba pake ndi zokutira zosavala komanso kutentha kwambiri, zomwe zimawapangitsa kukhala oyenera kudulidwa mosiyanasiyana.

2, Gulu la zida zamakina a CNC

Pali mitundu yosiyanasiyana yaCNC makina mpherozida, zomwe zitha kugawidwa m'mitundu yosiyanasiyana malinga ndi magawo osiyanasiyana. Zotsatirazi ndi njira zodziwika bwino zamagulu:

(1) Zosankhidwa ndi zida

Zida zodulira zophatikizika

Zida zodulira zophatikizika zimatanthawuza zida zomwe gawo lawo logwirira ntchito ndi shank zimapangidwira zonse, monga mphero, zobowoleza, etc. Chida chophatikizira chodulira chimakhala ndi dongosolo losavuta komanso mphamvu yayikulu, koma ndizovuta kupanga ndipo zimakhala zokwera mtengo. Ndi oyenera pokonza mbali ndi akalumikidzidwa osavuta ndi mkulu mwatsatanetsatane zofunika.

Zida zodulira mkati

Zida zodulira zophatikizika ndi zida zomwe zimaphatikizira tsamba kapena mano pathupi lodulira, monga mphero zopindika, zida zotembenuza, ndi zina. Masamba kapena mano a zida zodulira zophatikizika amatha kupangidwa ndi zinthu zosiyanasiyana ndi mawonekedwe a geometric kuti akwaniritse zofunikira zosiyanasiyana zogwirira ntchito, ndikukhala ndi zosinthika komanso zachuma.

Mtundu wapadera wa zida zodulira

Zida zodulira zamtundu wapadera zimatanthawuza zida zomwe zimapangidwira kuti zikwaniritse zofunikira zina zapadera, monga zida zopangira, zida zophatikizika, ndi zina. Zida zodulira zopangidwa zimatha kukonza pamwamba pazigawo zowoneka bwino, monga zida zodulira mphero, odula spline mphero, etc; Zida zodulira zophatikizika zimatha kumaliza masitepe angapo pakudulira kumodzi, monga kubowola ndi mphero zida zodulira zophatikizika, zida zotopetsa ndi mphero zodulira, etc.

(2) Gulu ndi zida

Zida zodulira zitsulo zothamanga kwambiri

Chitsulo chothamanga kwambiri ndi mtundu wachitsulo cha alloy chapamwamba chomwe chimakhala ndi zinthu zambiri zophatikizira monga tungsten, chromium, ndi vanadium. Zida zodulira zitsulo zothamanga kwambiri zimakhala ndi kulimba komanso kugaya bwino, ndipo zimatha kupirira katundu wambiri. Nthawi zambiri amagwiritsidwa ntchito pokonza magawo omwe ali ndi mawonekedwe ovuta komanso zofunikira zolondola kwambiri, monga kubowola, matepi, odula mphero, ndi zina zotero. Malingana ndi ntchito zosiyanasiyana, zida zodulira zitsulo zothamanga kwambiri zimatha kugawidwa m'magulu ambiri azitsulo zothamanga kwambiri komanso zitsulo zothamanga kwambiri.

Chitsulo cha Universal High-liwiro: Kulimba kwake kumayambira 62 mpaka 69HRC, imakhala ndi kukana kovala, kulimba kwambiri komanso kulimba, ndipo liwiro lodulira nthawi zambiri silikhala lalitali kuposa 45 mpaka 60m / min, zomwe sizoyenera kudula mwachangu.

Chitsulo chothamanga kwambiri: Ndichitsulo chomwe chimakhala ndi kukana kutentha kwambiri komanso kukana kuvala komwe kumapezeka powonjezera zomwe zili mu carbon ndi vanadium pamaziko a chitsulo chothamanga kwambiri. Chitsulo chothamanga kwambiri chimakhala ndi kuuma bwino kofiira, ndipo chikhoza kukhalabe ndi kuuma kwa 60HRC pa 620-660 ℃. Kukhalitsa kwake ndi 2-3.5 kuwirikiza kawiri-cholinga chachitsulo chothamanga kwambiri. Chitsulo chothamanga kwambiri chimagwiritsidwa ntchito pokonza zinthu zovuta ku makina monga ma aloyi otentha kwambiri ndi titaniyamu.

Zida zodula aloyi zolimba

Aloyi yolimba amapangidwa ndi ufa zitsulo ndondomeko ntchito kuuma mkulu, mkulu kusungunuka zitsulo carbides (monga tungsten carbide, titaniyamu carbide, etc.) ufa ndi zomangira (monga cobalt, faifi tambala, etc.). Zida zodulira zolimba zolimba zimakhala ndi mawonekedwe olimba kwambiri, kukana kwabwino kwa kuvala, komanso kukana kutentha kwakukulu, ndi liwiro lodulira la 100-300m / min, oyenera kudula mwachangu komanso makina okhwima. Zida zodulira zolimba za alloy zitha kugawidwa mu tungsten cobalt (YG), tungsten titanium cobalt (YT), ndi tungsten titanium tantalum (niobium) cobalt (YW) kutengera kapangidwe kake ndi magwiridwe antchito.

Ma aloyi olimba a Tungsten cobalt (YG): Ma aloyi olimba a YG amakhala ndi cobalt wambiri komanso kulimba kwabwino, kuwapangitsa kukhala oyenera kukonza zinthu zosasunthika monga chitsulo choponyedwa ndi zitsulo zopanda chitsulo.

Ma aloyi olimba a Tungsten titanium cobalt (YT): Ma aloyi olimba a YT ali ndi titaniyamu wambiri, kuuma bwino komanso kukana kuvala, ndipo ndi oyenera kukonza zida zapulasitiki monga chitsulo.

Tungsten titaniyamu tantalum (niobium) cobalt (YW) aloyi yolimba: YW aloyi olimba amaphatikiza ubwino wa YG ndi YT aloyi zolimba, ndi kuuma mkulu, kuvala kukana, kukana kutentha, ndi kulimba, oyenera pokonza zipangizo zosiyanasiyana, makamaka zovuta makina zipangizo monga zitsulo zosapanga dzimbiri ndi kutentha zosagwira zitsulo.

Zida zodulira zokutira

Zida zodulira zophimbidwa zimakutidwa ndi chosanjikiza chosavala komanso chopanda kutentha kwambiri, monga TiC, TiN, Al2O3, ndi zina zambiri, pamwamba pa aloyi yolimba kapena zida zodulira zitsulo zothamanga kwambiri. Zida zodulira zokutira zimatha kusintha kwambiri kuuma kwa pamwamba, kukana kuvala, komanso kukana kutentha kwa zida zodulira, ndikukulitsa moyo wawo wautumiki. Zida zodulira zokutira ndizoyenera pamikhalidwe yosiyanasiyana yodulira, makamaka kudula kothamanga kwambiri komanso kudula kowuma.

Zida zodulira Ceramic

Zida zodulira ceramic zimapangidwa makamaka ndi zida za ceramic monga alumina (Al2O3) ndi silicon nitride (Si3N4), zomwe zimatenthedwa kutentha kwambiri. Zida zodulira ceramic zili ndi zabwino monga kuuma kwakukulu, kukana bwino kuvala, kukana kutentha kwambiri, komanso kukhazikika kwamankhwala. Kuthamanga kwachangu kumatha kufika 500-1000m / min, kuwapanga kukhala oyenera kudula mwachangu komanso kukonza bwino. Komabe, zida zodulira ceramic zimakhala ndi brittleness kwambiri komanso kukana kopanda mphamvu. Mukawagwiritsa ntchito, samalani kuti musapewe kuchulukirachulukira.

Zida zodulira ma cubic boron nitride

Cubic boron nitride (CBN) ndi chinthu cholimba kwambiri chomwe chimakhala ndi kuuma kwachiwiri kwa diamondi. Zida zodulira za cubic boron nitride zili ndi zabwino monga kuuma kwambiri, kukana bwino kuvala, kukana kutentha kwambiri, komanso kukhazikika kwamankhwala. Kuthamanga kwachangu kumatha kufika 1000-2000 m / min, kuwapanga kukhala oyenera kudula kothamanga kwambiri komanso makina olondola azinthu zolimba kwambiri monga chitsulo chozimitsidwa ndi chitsulo chosungunuka.

Zida zodulira diamondi

Daimondi ndiye chinthu chovuta kwambiri m'chilengedwe, ndipo zida zodulira diamondi zimakhala zolimba kwambiri, kukana kuvala, komanso matenthedwe amafuta. Kuthamanga kwachangu kumatha kufika 2000-5000m / min, kuwapanga kukhala oyenera kudula mwachangu komanso kukonza bwino kwazinthu zopanda chitsulo komanso zopanda zitsulo. Komabe, zida zodulira diamondi ndizokwera mtengo komanso sizoyenera kupangira zida zachitsulo zokhala ndi chitsulo, popeza ma diamondi amakumana ndi mankhwala ndi chitsulo pakutentha kwambiri.

3, Kusankhidwa kwa zida zodulira makina a CNC mphero

Pali mitundu yosiyanasiyana ya zida zomwe zimagwiritsidwa ntchito pa makina a CNC, chilichonse chili ndi mawonekedwe ake apadera komanso momwe angagwiritsire ntchito. Posankha zida zida, m'pofunika kuganizira mozama zinthu monga zinthu za workpiece, processing luso, kudula mikhalidwe, etc., kuti asankhe bwino kwambiri chida chuma.

(1) Zizindikiro za machitidwe a zida zodulira zida zodulira zitsulo

Zida zodulira zida zodulira zitsulo nthawi zambiri zimafunikira kukhala ndi zizindikiro zingapo zogwirira ntchito, zomwe kuuma, mphamvu, kuuma kofiyira, kukhathamiritsa kwamafuta, etc. ndizofunikira kwambiri.

Kuuma ndi kuthekera kwa zida za zida zokana kuvala, ndipo kulimba kwapamwamba, ndipamene chidacho chimatha kuvala. Mphamvu ndi kuthekera kwa zida zolimbana ndi kuthyoka ndi kupunduka, ndipo zida zolimba kwambiri zimatha kupirira mphamvu zodulira. Kuuma kofiira kumatanthawuza kuthekera kwa zida zothandizira kuti zikhalebe zolimba pa kutentha kwakukulu, ndipo zida zokhala ndi kuuma kofiira bwino ndizoyenera kudula kwambiri. Kutentha kwamafuta kumakhudzanso kutentha kwa zida zodulira. Zida zokhala ndi matenthedwe abwino zimatha kutumiza kutentha kwachangu ndikuchepetsa kutentha kwa zida.

(2) Zida zabwino kwambiri

Chida choyenera chiyenera kukhala ndi kuuma ndi mphamvu, komanso kuuma kwabwino kofiira, kutsekemera kwamafuta, kukana kuvala, ndi kulimba. Komabe, muzogwiritsira ntchito, zimakhala zovuta kupeza chida chomwe chimakwaniritsa zofunikira zonse, kotero ndikofunikira kuyeza ndikusankha malinga ndi momwe zinthu ziliri.

(3) Zomwe zimagwiritsidwa ntchito podula zida zomwe zimagwiritsidwa ntchito

Pochita kukonza, zida zodulira zolimba zolimba ndi zida zomata zimagwiritsidwa ntchito kwambiri chifukwa chakuchita bwino kwambiri.

Zida zodulira zolimba za alloy zimakhala ndi kuuma kwakukulu komanso kukana kuvala, zomwe zimatha kutengera zomwe zimafunikira pakudulira kothamanga kwambiri komanso makina okhwima. Zida zodulira zolimba zokhala ndi aloyi, pamaziko a zida zodulira zolimba, zimapititsa patsogolo magwiridwe antchito awo ndikuwonjezera moyo wawo wautumiki powaphimba ndi zokutira zosavala komanso zosatentha kwambiri.

Kwa zida zina zovuta kupanga makina, monga ma aloyi otentha kwambiri, ma aloyi a titaniyamu, ndi zina zambiri, zida zodulira za kiyubiki boron nitride ndi zida zodulira diamondi zimakhala ndi mwayi wapadera. Zida zodulira za kiyubiki za boron nitride zimakhala ndi kuuma kwakukulu komanso kuuma kofiira bwino, komwe kumatha kudula zida zolimba kwambiri; Zida zodulira diamondi zimakhala ndi kuuma kwambiri komanso kusinthasintha kwamafuta, zomwe zimawapangitsa kukhala oyenera kukonza bwino zinthu zopanda chitsulo komanso zopanda zitsulo.

Ngakhale zida zodulira zitsulo zothamanga kwambiri sizikhala zolimba komanso zosavala ngati zida zodulira aloyi zolimba, zimakhalabe ndi ntchito zina pokonza magawo owoneka bwino komanso otsika kwambiri chifukwa cha kulimba kwawo komanso kugaya.

Zida zodulira Ceramic zimakhala ndi kuuma kwakukulu komanso kukana kwabwino, koma ndizowonongeka komanso zoyenera kudula mwachangu komanso kukonza bwino.

4, Zomwe zimathandizira pakusankha zida zamakina a CNC mphero

Posankha zida za makina a CNC mphero, zinthu zotsatirazi ziyenera kuganiziridwa mozama:

(1) Kugwiritsa ntchito zida zamakina

Mitundu yosiyanasiyana ndi mafotokozedwe a makina a CNC mphero ali ndi makhalidwe osiyanasiyana ogwira ntchito, monga liwiro la spindle, mlingo wa chakudya, mphamvu, torque, ndi zina zotero. Kusankhidwa kwa zida zodulira kuyenera kufanana ndi ntchito ya makina opangira makina kuti atulutse mphamvu zake. Mwachitsanzo, pamakina othamanga kwambiri, zida zoyenera zodulira zothamanga kwambiri ziyenera kusankhidwa, monga zida zokutira zolimba, zida za ceramic, ndi zina zambiri; Pamakina amphero amphamvu kwambiri, zida zodulira zokhala ndi mphamvu zambiri komanso kuuma zimatha kusankhidwa, monga zida zodulira zolimba zolimba.

(2) Zida zogwirira ntchito

Kuchita kwa zida zogwirira ntchito kumakhudza kwambiri kusankha zida. Osiyana workpiece zipangizo zosiyanasiyana kuuma, mphamvu, kulimba, matenthedwe madutsidwe, etc. Mwachitsanzo, pokonza zipangizo Chimaona ngati chitsulo choponyedwa, YG mtundu zolimba aloyi kudula zida akhoza kusankhidwa; Pamene pokonza zipangizo pulasitiki monga zitsulo, ndi m'pofunika kusankha YT mtundu zolimba aloyi kudula zida kapena TACHIMATA kudula zida; Mukakonza zovuta zamakina monga ma aloyi otentha kwambiri ndi ma aloyi a titaniyamu, zida zodulira za cubic boron nitride kapena zida zodulira diamondi ziyenera kusankhidwa.

(3) Pulogalamu yokonza

Mtundu wa makina opangira makina (monga makina okhwima, makina opangidwa ndi theka, makina olondola) ndi magawo odulira (monga kudula liwiro, kuchuluka kwa chakudya, kudula kuya) kumakhudzanso kusankha zida zodulira. Pamakina ovuta, zida zodulira zokhala ndi mphamvu zambiri komanso zolimba zomwe zimatha kupirira mphamvu zazikulu zodulira ziyenera kusankhidwa, monga zida zodulira zolimba zolimba; Mukakonza mwatsatanetsatane, zida zolondola kwambiri komanso zapamwamba zapamwamba ziyenera kusankhidwa, monga zida zomata zolimba kapena zida za ceramic.

(4) Kudula ndalama

Kukula kwa kuchuluka kwa kudula kumatsimikizira mwachindunji mphamvu yodulira ndi kudula kutentha komwe kumayendetsedwa ndi chida. Mukakonza ndi kudula kwakukulu, zida zodulira zokhala ndi mphamvu zambiri komanso kukana kutentha kwabwino ziyenera kusankhidwa; Popanga makina ocheperako pang'ono, zida zodulira zolimba kwambiri komanso kukana kwabwino zimatha kusankhidwa.

5, Masitepe ndi njira kusankha zida kudula makina CNC mphero

Posankha CNC makina mphero zida, njira zotsatirazi zikhoza kutsatiridwa:

(1) Dziwani zofunikira pakukonza

Choyamba, m'pofunika kumveketsa bwino mawonekedwe, kukula, zofunikira zolondola, zofunikira zapamwamba, ndi njira zopangira (monga makina okhwima, makina osakanikirana, ndi makina olondola) a magawo okonzedwa.

(2) Unikani zinthu za workpiece

Unikani ntchito ya workpiece zakuthupi, kuphatikizapo kuuma, mphamvu, toughness, matenthedwe madutsidwe, etc., kudziwa zipangizo zoyenera chida.

(3) Sankhani mtundu wa chida

Malinga ndi zofunika processing ndi workpiece zipangizo, kusankha mtundu woyenera chida, monga mphero mapeto, kubowola, odula wotopetsa, etc.

(4) Dziwani magawo a zida

Dziwani m'mimba mwake, kutalika, kuchuluka kwa m'mphepete, ngodya ya helix, ngodya yotsogola, ngodya yodutsa, ndi magawo ena a chida chodulira potengera magawo odulira ndi magwiridwe antchito a makina.

(5) Sankhani zida zodulira ndi ogulitsa

Pambuyo pozindikira mtundu ndi magawo a zida zodulira, sankhani mitundu yodziwika bwino komanso ogulitsa odalirika kuti muwonetsetse kuti zida ndi ntchito zogulitsa pambuyo pake.

6, Kugwiritsa ntchito ndi kukonza zida zamakina a CNC

Kusankha chida choyenera ndi gawo loyamba chabe, ndipo kugwiritsa ntchito moyenera ndi kukonza chida ndikofunikira kwambiri pakuwonetsetsa kuti makinawa ali abwino komanso kukulitsa moyo wa zida.

(1) Kuyika zida zodulira

Mukayika chidacho, ndikofunikira kuwonetsetsa kulondola kwapakati pakati pa chida ndi chida, kuonetsetsa kuti chidacho chikukhazikika komanso molondola. Panthawi imodzimodziyo, chidwi chiyenera kuperekedwa ku kayendetsedwe ka unsembe ndi malo a zida kuti apewe zolakwika za unsembe zomwe zingayambitse zolakwika za makina kapena kuwonongeka kwa zida.

(2) Kusankhidwa kwa magawo odulira zida zodulira

Kusankha koyenera kwa magawo odulira ndiye chinsinsi chowonetsetsa kuti kudula bwino komanso kukulitsa moyo wa chida. Kudula magawo kumaphatikizapo kudula liwiro, kuchuluka kwa chakudya, kudula kuya, ndi zina zotero, ndipo kuyenera kuganiziridwa mozama kutengera zinthu monga zida, zida zogwirira ntchito, ndi njira yopangira makina. Nthawi zambiri, mkati mwa zida zovomerezeka zodulira, kuthamanga kwapamwamba kwambiri komanso mitengo yaying'ono ya chakudya iyenera kusankhidwa kuti makina azigwira bwino ntchito komanso kuti akhale abwino.

(3) Kuziziritsa ndi kudzoza kwa zida zodulira

Panthawi yodula, njira zoyenera zoziziritsira ndi zopaka mafuta ziyenera kugwiritsidwa ntchito kuchepetsa kutentha, kuchepetsa kuvala kwa zida, komanso kukonza makina opangira makina. Njira zoziziritsira komanso zokometsera zodziwika bwino zimaphatikizapo kudula kuziziritsa kwamadzimadzi, kuziziritsa mpweya, kuthira mafuta amafuta, ndi zina.

(4) Kusamalira ndi kusamalira zida zodulira

Pambuyo pokonza, tchipisi ndi madontho amafuta pazida zodulira ziyenera kutsukidwa munthawi yake, ndipo kuvala kwa zida kuyenera kuyang'aniridwa. Ngati pali kuvala kulikonse, iyenera kukongoletsedwa kapena kusinthidwa munthawi yake. Panthawi imodzimodziyo, kukonza nthawi zonse kuyenera kuchitidwa pazida zodulira, monga kugwiritsa ntchito mafuta oletsa dzimbiri, kuyang'ana kulondola kwa chida chogwiritsira ntchito, ndi zina zotero, kuonetsetsa kuti ntchito ndi moyo wautumiki wa zida zodulira zikugwira ntchito.

7, Mapeto

Kusankhidwa kwa zida zodulira makina a CNC mphero ndi ntchito yovuta komanso yofunika kwambiri yomwe imafuna kuganizira mozama zinthu zingapo monga makina ogwiritsira ntchito, zida zogwirira ntchito, mapulogalamu a Machining, ndi kudula ndalama. Kusankha ndi kugwiritsa ntchito zida zodulira molondola sikungowonjezera ubwino wa makina ndi kupanga, komanso kuchepetsa ndalama zopangira ndikuwonjezera moyo wautumiki wa zida zamakina. Choncho, pakupanga kwenikweni, chida choyenera kwambiri chiyenera kusankhidwa potengera momwe zinthu zilili pokonzekera komanso momwe ntchitoyo ikugwiritsidwira ntchito, komanso kugwiritsa ntchito ndi kukonza kasamalidwe ka chidacho kuyenera kulimbikitsidwa kuti athe kugwiritsa ntchito bwino ubwino wa makina a CNC mphero ndikupereka chithandizo champhamvu pa chitukuko cha makampani opanga zinthu.