Pankhani yokonza makina amakono, makina obowola ndi makina a CNC mphero ndi zida ziwiri zodziwika komanso zofunika kwambiri zamakina, zomwe zimakhala ndi kusiyana kwakukulu kwa ntchito, kapangidwe kake, ndi zochitika zogwiritsira ntchito. Pofuna kukupatsirani chidziwitso chakuya komanso chokwanira cha mitundu iwiri ya zida zamakina, wopanga makina a CNC akupatsirani kufotokozera mwatsatanetsatane pansipa.

1. Kusiyanitsa kolimba

The rigidity makhalidwe makina kubowola

Makina obowola amapangidwa makamaka kuti athe kupirira mphamvu zazikulu zowongoka, zokhala ndi mphamvu zochepa zofananira. Izi ndichifukwa choti njira yayikulu yopangira makina obowola ndikubowola, ndipo pobowola makamaka amabowola motsatira njira yowongoka panthawi yogwira ntchito, ndipo mphamvu yomwe imagwiritsidwa ntchito pachogwirira ntchito imakhazikika kwambiri panjira ya axial. Chifukwa chake, kapangidwe ka makina obowola alimbikitsidwa molunjika kuti atsimikizire kukhazikika, kuchepetsa kugwedezeka ndi kupatuka pakubowola.

Komabe, chifukwa cha kufooka kwa makina obowola kuti athe kulimbana ndi mphamvu zotsatizana nazo, izi zimachepetsanso ntchito yawo muzochitika zina zovuta za makina. Pamene kuli kofunika kuchita mbali Machining pa workpiece kapena pamene pali kusokoneza kwambiri ofananira nawo pobowola ndondomeko kubowola, makina pobowola sangathe kuonetsetsa Machining kulondola ndi bata.

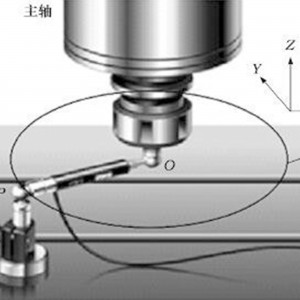

Zofunikira pakukhazikika kwa makina a CNC mphero

Mosiyana ndi makina pobowola, CNC mphero makina amafuna kukhazikika bwino chifukwa mphamvu kwaiye pa ndondomeko mphero zovuta kwambiri. Mphamvu yogaya simangophatikizanso mphamvu zazikulu zowongoka, komanso zimafunika kupirira mphamvu zazikulu zam'mbali. Pa mphero ndondomeko, kukhudzana m'dera pakati pa mphero wodula ndi workpiece ndi lalikulu, ndi chida atembenuza pamene kudula pamodzi yopingasa malangizo, chifukwa mphamvu mphero akuchita angapo malangizo.

Pofuna kuthana ndi zovuta zoterezi, mapangidwe a makina a CNC mphero nthawi zambiri amakhala olimba komanso okhazikika. Zigawo zazikulu za chida cha makina, monga bedi, mizati, ndi njanji zowongolera, zimapangidwa ndi zida zamphamvu kwambiri komanso zida zokongoletsedwa bwino kuti zithandizire kukhazikika komanso kukana kugwedezeka. Kusasunthika kwabwino kumathandizira makina a CNC mphero kukhalabe ndi makina olondola kwambiri pomwe akulimbana ndi mphamvu zazikulu zodulira, kuwapanga kukhala oyenera kukonza mawonekedwe osiyanasiyana ovuta komanso magawo olondola kwambiri.

2.Kusiyana kwamapangidwe

Makhalidwe amapangidwe a makina obowola

Mapangidwe a makina obowola ndi osavuta, ndipo nthawi zambiri, malinga ngati chakudya choyimirira chikukwaniritsidwa, chimatha kukwaniritsa zofunikira. Makina obowola nthawi zambiri amakhala ndi bedi, mzati, bokosi la spindle, benchi yogwirira ntchito, ndi makina opangira chakudya.

Bedi ndilo gawo lalikulu la makina obowola, omwe amagwiritsidwa ntchito pothandizira ndi kukhazikitsa zigawo zina. Mzerewu umayikidwa pa bedi kuti upereke chithandizo cha bokosi lalikulu la axle. Bokosi la spindle limakhala ndi chopondera komanso njira yosinthira liwiro, yomwe imagwiritsidwa ntchito kuyendetsa kuzungulira kwa kubowola. Benchi yogwirira ntchito imagwiritsidwa ntchito kuyika zida zogwirira ntchito ndipo imatha kusinthidwa mosavuta ndikuyika. Dongosolo la chakudya limayang'anira kayendedwe ka axial feed pabowolo kuti akwaniritse kuya kwake pakubowola.

Chifukwa cha njira yosavuta yopangira makina obowola, mapangidwe awo ndi ophweka ndipo mtengo wake ndi wochepa. Koma dongosolo losavutali limachepetsanso magwiridwe antchito ndi makina obowola.

Kapangidwe ka makina a CNC mphero

Kapangidwe ka makina a CNC mphero ndizovuta kwambiri. Sichingofunika kupeza chakudya choyimirira, koma chofunika kwambiri, chiyeneranso kukhala ndi ntchito yopingasa yotalikirapo komanso yodutsa. CNC makina mphero zambiri wapangidwa ndi mbali monga bedi, mzati, worktable, chishalo, bokosi spindle, dongosolo CNC, dongosolo chakudya pagalimoto, etc.

Bedi ndi mzati zimapereka chithandizo chokhazikika cha chida cha makina. Benchi yogwirira ntchito imatha kusuntha mozungulira kuti ikwaniritse chakudya cham'mbali. Chishalocho chimayikidwa pamtanda ndipo chimatha kuyendetsa bokosi la spindle kuti lisunthike molunjika, kupeza chakudya chautali. Bokosi la spindle limakhala ndi masipingo ochita bwino kwambiri komanso zida zosinthira mwachangu kuti zikwaniritse zofunikira zaukadaulo wosiyanasiyana.

Dongosolo la CNC ndiye gawo lalikulu la makina opangira mphero a CNC, omwe ali ndi udindo wolandila malangizo apulogalamu ndikuwasintha kukhala ma siginecha owongolera pamakina aliwonse a zida zamakina, kukwaniritsa machining achindunji. Dongosolo loyendetsa chakudya limatembenuza malangizo a dongosolo la CNC kukhala mayendedwe enieni a tebulo logwirira ntchito ndi chishalo kudzera muzinthu monga ma mota ndi zomangira, kuwonetsetsa kuti makinawa ali olondola komanso apamwamba.

3.Processing ntchito

Mphamvu yopangira makina obowola

Makina obowola makamaka ndi chipangizo chomwe chimagwiritsa ntchito pobowola pobowola ndi kukonza zida. Muzochitika zachilendo, kuzungulira kwa kubowola ndikusuntha kwakukulu, pamene kayendedwe ka axial kwa makina obowola ndi kayendedwe ka chakudya. Makina obowola amatha kuchita kudzera m'dzenje, dzenje lakhungu ndi ntchito zina zamakina pazida zogwirira ntchito, ndipo zimatha kukwaniritsa zofunikira zosiyanasiyana pakubowola ndikusintha ma diameter osiyanasiyana ndi mitundu.

Kuphatikiza apo, makina obowola amathanso kuchita ntchito zina zosavuta zoboola komanso kubowola. Komabe, chifukwa cha zofooka zake zamapangidwe komanso magwiridwe antchito, makina obowola sangathe kupanga makina owoneka bwino pamwamba pazida zogwirira ntchito, monga malo athyathyathya, ma grooves, magiya, ndi zina zambiri.

Mitundu yosiyanasiyana ya makina a CNC mphero

CNC makina mphero ndi osiyanasiyana osiyanasiyana luso processing. Itha kugwiritsa ntchito odula mphero kuti akonze malo athyathyathya a zida zogwirira ntchito, komanso mawonekedwe ovuta monga ma grooves ndi magiya. Kuphatikiza apo, makina opangira mphero a CNC amathanso kukonza zida zogwirira ntchito zomwe zimakhala ndi mbiri zovuta, monga malo opindika ndi malo osakhazikika, pogwiritsa ntchito zida zapadera zodulira ndi njira zamapulogalamu.

Poyerekeza ndi makina pobowola, CNC makina mphero ndi apamwamba Machining dzuwa, liwiro mofulumira, ndipo akhoza kukwaniritsa apamwamba Machining molondola ndi pamwamba khalidwe. Izi zapangitsa makina a CNC mphero amagwiritsidwa ntchito kwambiri m'magawo monga kupanga nkhungu, zakuthambo, ndi zida zamagalimoto.

4.Zida ndi zosintha

Zida ndi zida zopangira makina obowola

Chida chachikulu chomwe chimagwiritsidwa ntchito pamakina obowola ndikubowola, ndipo mawonekedwe ndi kukula kwa chobowolacho zimasankhidwa molingana ndi zofunikira pakukonza. Pobowola, zosintha zosavuta monga pliers, V-blocks, ndi zina zambiri zimagwiritsidwa ntchito kuyika ndi kukakamiza chogwirira ntchito. Chifukwa chakuti mphamvu yogwiritsidwa ntchito ndi makina obowola imayang'ana kwambiri kumbali ya axial, mapangidwe ake ndi ophweka, makamaka kuonetsetsa kuti chogwirira ntchito sichidzasuntha kapena kuzungulira panthawi yobowola.

Zida ndi zida zamakina a CNC mphero

Pali mitundu yosiyanasiyana ya zida kudula ntchito CNC makina mphero, kuphatikizapo mpira mapeto mphero, mapeto mphero, nkhope mphero, etc. kuwonjezera wamba odula mphero. Mitundu yosiyanasiyana ya zida zodulira ndizoyenera njira zosiyanasiyana zogwirira ntchito komanso zofunikira za mawonekedwe. Mu CNC mphero, zofunika kamangidwe ka fixtures ndi apamwamba, ndi zinthu monga kugawa mphamvu kudula, malo kulondola kwa workpiece, ndi kukula kwa clamping mphamvu ayenera kuganiziridwa kuonetsetsa kuti workpiece sakumana kusamutsidwa ndi mapindikidwe pa ndondomeko Machining.

Pofuna kukonza Machining Mwachangu ndi olondola, CNC mphero makina zambiri ntchito mindandanda yamasewera apadera ndi mindandanda yamasewera, monga mindandanda yamasewera hayidiroliki, etc. Pa nthawi yomweyo, CNC mphero makina akhoza kukwaniritsa mofulumira kusintha kwa zida zosiyanasiyana kudula pogwiritsa ntchito zida basi kusintha zipangizo, kupititsa patsogolo kusinthasintha ndi dzuwa la processing.

5. Mapulogalamu ndi Ntchito

Kukonzekera ndi kugwiritsa ntchito makina obowola

Kukonzekera kwa makina obowola ndikosavuta, nthawi zambiri kumangofunika kukhazikitsidwa kwa magawo monga kuya kwa kubowola, kuthamanga, ndi kuchuluka kwa chakudya. Ogwiritsa ntchito amatha kumaliza kukonza makinawo pogwiritsira ntchito pamanja chogwirira kapena batani la chida cha makina, ndipo amathanso kugwiritsa ntchito dongosolo losavuta la CNC pakukonza ndi kuwongolera.

Chifukwa chaukadaulo wosavuta wopangira makina obowola, ntchitoyo ndiyosavuta, ndipo zofunikira zaukadaulo kwa ogwiritsa ntchito ndizochepa. Koma izi zimachepetsanso kugwiritsa ntchito makina obowola m'magawo ovuta.

Kukonzekera ndi kugwiritsa ntchito makina a CNC mphero

Kukonzekera kwa makina a CNC mphero ndizovuta kwambiri, zomwe zimafuna kugwiritsa ntchito mapulogalamu apamwamba monga MasterCAM, UG, ndi zina zotero, kuti apange mapulogalamu opangira makina otengera zojambula ndi zofunikira za makina a zigawozo. Panthawi yokonza mapulogalamu, zinthu zambiri monga njira ya zida, magawo odulira, ndi kutsata ndondomeko ziyenera kuganiziridwa kuti zitsimikizire kuti makinawa ndi olondola komanso ogwira ntchito.

Kumbali ya ntchito, CNC makina mphero zambiri okonzeka ndi kukhudza zowonetsera kapena mapanelo ntchito. Ogwira ntchito ayenera kudziwa bwino mawonekedwe a ntchito ndi ntchito za dongosolo la CNC, kuti athe kulowetsa molondola malangizo ndi magawo, ndikuyang'anira momwe alili panthawi ya makina. Chifukwa chaukadaulo wamakina opangira makina a CNC mphero, pakufunika kwambiri luso laukadaulo komanso chidziwitso cha akatswiri, zomwe zimafunikira maphunziro apadera ndi machitidwe kuti adziwe bwino.

6. Munda wa ntchito

Zitsanzo zogwiritsira ntchito makina obowola

Chifukwa cha mawonekedwe ake osavuta, otsika mtengo, komanso ntchito yabwino, makina obowola amagwiritsidwa ntchito kwambiri m'mashopu ena ang'onoang'ono okonza makina, malo ochitirako kukonza, komanso mabanja omwe amakonza. Amagwiritsidwa ntchito kwambiri pokonza magawo okhala ndi zida zosavuta komanso zofunikira zochepa, monga magawo amtundu wa dzenje, magawo olumikizira, ndi zina zambiri.

M'mabizinesi ena opanga zinthu zambiri, makina obowola amathanso kugwiritsidwa ntchito pokonza njira zosavuta, monga kubowola mabowo pazitsulo. Komabe, pakukonza magawo owoneka bwino kwambiri komanso ovuta, makina obowola sangathe kukwaniritsa zofunikira.

Kuchuluka kwa kugwiritsa ntchito makina a CNC mphero

CNC makina mphero akhala chimagwiritsidwa ntchito m'minda monga kupanga nkhungu, ndege, zigawo magalimoto, zida zamagetsi, etc. chifukwa cha ubwino wa mkulu Machining kulondola, dzuwa mkulu, ndi ntchito zamphamvu. Itha kugwiritsidwa ntchito pokonza zisankho zosiyanasiyana zowoneka bwino, magawo olondola, zigawo zamabokosi, ndi zina zambiri, ndipo zimatha kukwaniritsa zosowa zamasiku ano zopangira zolondola kwambiri komanso zogwira mtima kwambiri.

Makamaka m'mafakitale ena apamwamba kwambiri, makina opangira mphero a CNC akhala zida zofunikira kwambiri, zomwe zimagwira ntchito yofunika kwambiri pakuwongolera zinthu, kufupikitsa kuzungulira kwakupanga, komanso kuchepetsa ndalama.

7, Kuyerekeza zitsanzo Machining

Kuti zambiri mwachilengedwe kusonyeza kusiyana Machining zotsatira pakati pa makina pobowola ndi CNC makina mphero, awiri enieni Machining zitsanzo adzakhala poyerekeza pansipa.

Chitsanzo 1: Kukonza mbale yosavuta ya orifice

Kubowola makina processing: Choyamba, kukonza workpiece pa workbench, kusankha yoyenera kubowola pang'ono, kusintha pobowola kuya ndi mlingo chakudya, ndiyeno yambani makina kubowola pobowola processing. Chifukwa chakuti makina pobowola pobowola kokha pobowola ofukula, zofunika dzenje malo olondola ndi pamwamba khalidwe si mkulu, ndipo processing Mwachangu ndi otsika.

CNC mphero makina processing: Mukamagwiritsa ntchito makina CNC mphero pokonza, sitepe yoyamba ndi chitsanzo mbali mu 3D ndi kupanga dongosolo Machining malingana ndi ndondomeko Machining zofunika. Kenako ikani chogwirira ntchito pamwambo wodzipatulira, lowetsani pulogalamu yamakina kudzera mudongosolo la CNC, ndikuyamba chida cha makina opangira makina. CNC mphero makina akhoza kukwaniritsa imodzi Machining mabowo angapo kudzera mapulogalamu, ndipo akhoza kuonetsetsa kulondola malo ndi pamwamba khalidwe mabowo, kwambiri bwino Machining dzuwa.

Chitsanzo 2: Kukonza gawo la nkhungu zovuta

Kukonza makina obowola: Pazigawo zovuta za nkhungu zowoneka bwino ngati izi, makina obowola amalephera kumaliza ntchito zokonza. Ngakhale zitakonzedwa kudzera mu njira zina zapadera, zimakhala zovuta kuonetsetsa kuti makina ali olondola komanso apamwamba.

CNC mphero makina processing: Pogwiritsa ntchito ntchito zamphamvu za makina CNC mphero, n'zotheka choyamba Machining akhakula pa mbali nkhungu, kuchotsa ambiri owonjezera, ndiyeno kuchita theka mwatsatanetsatane ndi mwatsatanetsatane Machining, potsirizira pake kupeza mkulu-mwatsatanetsatane ndi apamwamba mbali nkhungu. Pa ndondomeko Machining, mitundu yosiyanasiyana ya zida angagwiritsidwe ntchito ndi kudula magawo akhoza wokometsedwa kusintha Machining Mwachangu ndi pamwamba khalidwe.

Poyerekeza zitsanzo ziwiri zomwe zili pamwambazi, zitha kuwoneka kuti makina obowola ndi oyenera kukonza dzenje losavuta, pomwe makina a CNC mphero amatha kukonza mawonekedwe osiyanasiyana ovuta komanso magawo olondola kwambiri.

8, Chidule

Mwachidule, pali kusiyana kwakukulu pakati pa makina obowola ndi makina a CNC mphero malinga ndi kukhazikika, kapangidwe kake, ntchito zogwirira ntchito, zida zopangira, ntchito zamapulogalamu, ndi magawo ogwiritsira ntchito. Makina obowola ali ndi mawonekedwe osavuta komanso otsika mtengo, ndipo ndi oyenera kubowola kosavuta komanso kukonza dzenje; Makina opangira mphero a CNC ali ndi mawonekedwe olondola kwambiri, kugwiritsa ntchito bwino kwambiri, komanso magwiridwe antchito ambiri, omwe amatha kukwaniritsa zofunikira zamakampani amakono kuti akonze zovuta.

Pakupanga kwenikweni, makina obowola kapena makina a CNC mphero ayenera kusankhidwa momveka bwino potengera ntchito zinazake zogwirira ntchito ndi zofunikira kuti akwaniritse zotsatira zabwino kwambiri komanso zopindulitsa zachuma. Pa nthawi yomweyo, ndi patsogolo mosalekeza luso ndi chitukuko cha makampani kupanga, pobowola makina ndi CNC mphero makina nawonso mosalekeza ndi angwiro, kupereka wamphamvu luso thandizo kwa chitukuko cha makina processing makampani.