Pa gawo la makampani opanga masiku ano, zida zamakina a CNC zakhala msana wa kupanga ndi kuthekera kwawo koyenera komanso kolondola. Zofunikira pakuwongolera makina pazigawo zazikulu za zida zamakina a CNC mosakayikira ndizofunikira zomwe zimatsimikizira kusankha kwa zida zamakina za CNC.

Zida zamakina a CNC zimagawidwa m'magulu osiyanasiyana monga zosavuta, zogwira ntchito mokwanira, komanso zolondola kwambiri chifukwa chakugwiritsa ntchito mosiyanasiyana, ndipo milingo yolondola imasiyana kwambiri. Zida zamakina osavuta a CNC zimagwirabe ntchito m'munda wamakono wa lathes ndi makina ophera, ndi kusamvana kocheperako kwa 0.01mm, ndikuyenda ndi kulondola kwa makina nthawi zambiri kuyambira 0.03 mpaka 0.05 mm kapena kupitilira apo. Ngakhale kulondola kumakhala kochepa, muzochitika zina za Machining kumene zofunikira zolondola sizili zovuta kwambiri, zida zosavuta zamakina a CNC zimagwira ntchito yosasinthika chifukwa cha phindu lawo lachuma ndi ntchito yosavuta.

Mosiyana kwambiri, zida zamakina za CNC zotsogola kwambiri zimapangidwira makamaka pazosowa zapadera zamakina, ndi kulondola kodabwitsa kwa 0.001mm kapena kuchepera. Zida zamakina olondola kwambiri a CNC nthawi zambiri zimagwiritsidwa ntchito m'magawo olondola kwambiri komanso otsogola monga zakuthambo ndi zida zamankhwala, kupereka chithandizo cholimba chaukadaulo popanga zida zovuta kwambiri komanso zofunikira kwambiri.

Pakuwona kulondola, zida zamakina a CNC zitha kugawidwa m'mitundu wamba komanso yolondola. Nthawi zambiri, pamakhala 20 mpaka 30 zowunikira zolondola pazida zamakina a CNC, koma zovuta kwambiri komanso zoyimilira ndizolondola kokhazikika kwa olamulira amodzi, olamulira amodzi mobwerezabwereza, komanso kuzungulira kwa chidutswa choyesera chopangidwa ndi nkhwangwa ziwiri kapena zingapo zolumikizidwa.

Kulondola kwa malo ndi kubwereza kobwerezabwereza kumathandizirana ndipo palimodzi kufotokozera kulondola kwatsatanetsatane kwa zigawo zosuntha za axis ya chida cha makina. Makamaka ponena za kulondola kobwerezabwereza, kumakhala ngati galasi, kuwonetseratu kukhazikika kwa malo otsetsereka pa malo aliwonse omwe ali mkati mwa sitiroko yake. Khalidweli limakhala mwala wapangodya woyezera ngati shaft imatha kugwira ntchito mokhazikika komanso modalirika, ndipo ndiyofunikira pakuwonetsetsa kuti chida cha makina chikugwira ntchito kwanthawi yayitali komanso kusasinthika kwaukadaulo wamakina.

Masiku ano CNC dongosolo mapulogalamu ali ngati mmisiri wanzeru, ndi wolemera ndi zosiyanasiyana zolakwa chipukuta misozi ntchito, wokhoza mochenjera kubwezera zolakwa dongosolo kwaiye ulalo uliwonse wa unyolo kufala chakudya molondola ndi stably. Kutengera maulalo osiyanasiyana a unyolo wopatsira mwachitsanzo, kusintha kwa zinthu monga chilolezo, kusinthika zotanuka, ndi kuuma kolumikizana sikukhazikika, koma kumawonetsa kusintha kwakanthawi kwakanthawi komwe kumasinthasintha monga kukula kwa benchi yogwira ntchito, kutalika kwa mtunda woyenda, komanso kuthamanga kwa malo oyenda.

M'makina ena otseguka ndi ma semi otsekedwa-loop feed servo, zida zoyendetsera makina pambuyo pazigawo zoyezera zimakhala ngati zombo zomwe zikupita patsogolo mumphepo ndi mvula, motengera zinthu zosiyanasiyana mwangozi. Mwachitsanzo, chodabwitsa cha matenthedwe elongation wa zomangira mpira zingachititse kutengeka mu malo enieni malo a workbench, potero kubweretsa kwambiri mwachisawawa zolakwika kwa Machining molondola. Mwachidule, ngati pali chisankho chabwino pakusankha, palibe kukayikira kuti zida zomwe zili ndi malo abwino kwambiri obwerezabwereza ziyenera kukhala patsogolo, kuwonjezera inshuwalansi yamphamvu ku khalidwe lokonzekera.

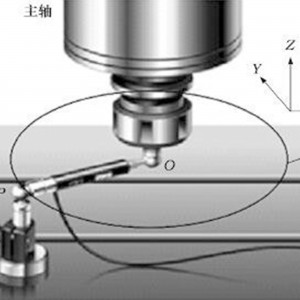

Kulondola kwa milling cylindrical surfaces kapena milling spatial grooves (ulusi), monga wolamulira wabwino woyezera ntchito ya chida cha makina, ndi chizindikiro chachikulu cha kuwunika mozama za servo zotsatirazi zoyenda za CNC olamulira (nkhwangwa ziwiri kapena zitatu) ndi ntchito yomasulira ya makina a CNC. Njira yabwino yodziwira chizindikiro ichi ndikuyesa kuzungulira kwa cylindrical pamwamba.

M'zochita kudula zidutswa mayeso pa CNC makina zida, mphero oblique lalikulu lalikulu anayi mbali Machining njira imasonyezanso mtengo wake wapadera, amene akhoza kuweruza molondola ntchito nkhwangwa awiri controllable mu liniya interpolation zoyenda. Pochita opareshoni yodulira iyi, ndikofunikira kuti muyike mosamala mphero yomwe imagwiritsidwa ntchito pokonza makinawo pa makina opota, kenako ndikuchita mphero mosamalitsa pachitsanzo chozungulira chomwe chimayikidwa pa benchi. Kwa zida zamakina ang'onoang'ono ndi apakati, kukula kwa chitsanzo chozungulira nthawi zambiri kumasankhidwa pakati pa ¥ 200 ndi ¥ 300. Mndandanda uwu wayesedwa muzochita ndipo ukhoza kuyesa bwino makina opangira makina.

Mukamaliza mphero, ikani mosamala chitsanzo chodulidwacho pa mita yozungulira ndikuyesa kuzungulira kwa malo ake opangidwa ndi makina pogwiritsa ntchito chida choyezera molondola. Pochita izi, ndikofunikira kuyang'ana ndikusanthula zotsatira zake mozama. Ngati pali zodziwikiratu mphero wodula kugwedera machitidwe pa milled cylindrical pamwamba, limatichenjeza kuti interpolation liwiro la chida makina kungakhale wosakhazikika; Ngati kuzungulira kopangidwa ndi mphero kukuwonetsa zolakwika zowoneka bwino za elliptical, nthawi zambiri zimawonetsa kuti zopindulitsa za machitidwe awiri owongolera olamulira mumayendedwe otanthauzira sizinagwirizane bwino; Pamene pali amasiya zizindikiro pa aliyense controllable olamulira kuyenda malangizo kusintha mfundo pa zozungulira padziko (ie, mu mosalekeza kudula zoyenda, kuyimitsa chakudya zoyenda pa malo enaake adzapanga kagawo kakang'ono zitsulo kudula zizindikiro pa Machining pamwamba), izi zikutanthauza kuti kutsogolo ndi n'zosiyana chilolezo cha olamulira sichinasinthidwe ku dziko labwino.

Lingaliro la kulondola kwa malo a axis limodzi limatanthawuza kusiyanasiyana kwa zolakwika zomwe zimapangidwa poyika mfundo iliyonse mkati mwa sitiroko ya axis. Zili ngati nyali yowunikira, yowunikira mwachindunji luso la makina a makina, ndipo mosakayika kukhala chimodzi mwa zizindikiro zovuta kwambiri za zida za makina a CNC.

Pakalipano, pali kusiyana kwina mu malamulo, matanthauzo, njira zoyezera, ndi njira zopangira deta za kulondola kwa malo amodzi pakati pa mayiko padziko lonse lapansi. Pachiyambi cha zosiyanasiyana CNC makina chida chitsanzo deta, wamba ndi ambiri anatchula mfundo monga American Standard (NAS), analimbikitsa mfundo ndi American Machine Tool opanga Association, German Standard (VDI), Japanese Standard (JIS), International Organisation for Standardization (ISO), ndi Chinese National Standard (GB).

Pakati pamiyezo yowoneka bwino iyi, miyezo ya ku Japan ndi yocheperako malinga ndi malamulo. Njira yoyezera imachokera pamtundu umodzi wa deta yokhazikika, ndiyeno mochenjera amagwiritsa ntchito ± mfundo kuti apanikize mtengo wolakwika ndi theka. Zotsatira zake, kulondola kwa malo komwe kumachitika pogwiritsa ntchito njira zoyezera za ku Japan nthawi zambiri kumasiyana kuwirikiza kawiri poyerekeza ndi miyezo ina.

Ngakhale kuti miyezo ina imasiyana m'mene amasamalirira deta, imakhala yozama m'nthaka ya ziwerengero zolakwika kuti awunike ndikuyesa kulondola kwa malo. Mwachindunji, pakulakwitsa kwina kwa malo omwe amawongolera makina a CNC, akuyenera kuwonetsa zolakwika zomwe zitha kuchitika nthawi masauzande oyika pakugwiritsa ntchito kwa nthawi yayitali chida cha makina mtsogolo. Komabe, potengera momwe zinthu ziliri, nthawi zambiri timatha kuchita maopaleshoni ochepa poyeza, nthawi zambiri 5 mpaka 7.

Kuweruza kolondola kwa zida zamakina a CNC kuli ngati ulendo wovuta wothetsa zithunzithunzi, womwe sunapezeke mwadzidzidzi. Zizindikiro zina zolondola zimafuna kuyang'anitsitsa mosamala ndi kusanthula zinthu zomwe zakonzedwa pambuyo pa ntchito yeniyeni ya makina a makina, zomwe mosakayikira zimawonjezera zovuta ndi zovuta za chiweruzo cholondola.

Kuti titsimikizire kusankhidwa kwa zida zamakina a CNC zomwe zimakwaniritsa zofunikira zopanga, tiyenera kufufuza mozama magawo olondola a zida zamakina ndikuchita kusanthula kwatsatanetsatane komanso mwatsatanetsatane musanapange zisankho zogula. Nthawi yomweyo, ndikofunikira kulumikizana mokwanira komanso mozama ndikusinthanitsa ndi opanga zida zamakina a CNC. Kumvetsetsa mulingo wa momwe wopanga amapangira, kukhwima kwa njira zowongolera zabwino, komanso kukwanira kwa ntchito zogulitsa pambuyo pakugulitsa kungapereke maziko ofunikira kwambiri pakusankha kwathu.

M'mawonekedwe ogwiritsira ntchito, mtundu ndi kulondola kwa zida zamakina a CNC ziyeneranso kusankhidwa mwasayansi komanso momveka bwino kutengera ntchito zamakina komanso zofunikira za magawo. Kwa magawo omwe ali ndi zofunikira zolondola kwambiri, zida zamakina zokhala ndi makina apamwamba kwambiri a CNC ndi zida zolondola kwambiri ziyenera kuganiziridwa patsogolo mosazengereza. Kusankha kumeneku sikungotsimikizira kuti ntchito yabwino kwambiri, komanso imapangitsa kuti ntchito ikhale yogwira ntchito, imachepetsa ndalama zowonongeka, ndipo imabweretsa phindu lalikulu lazachuma ku bizinesi.

Kuphatikiza apo, kuyezetsa mwatsatanetsatane komanso kukonza mosamala zida zamakina a CNC ndi njira zazikulu zowonetsetsa kuti magwiridwe antchito azikhala okhazikika komanso kukhala ndi luso laukadaulo kwambiri. Pozindikira mwachangu ndikuthana ndi zovuta zomwe zingachitike, moyo wautumiki wa zida zamakina ukhoza kukulitsidwa bwino, kuwonetsetsa kukhazikika ndi kudalirika kwaukadaulo wamakina. Mofanana ndi kusamalira galimoto yamtengo wapatali yothamanga, kuyang'anitsitsa mosalekeza ndi kukonza bwino kungathandize kuti iziyenda bwino pamsewu.

Mwachidule, kulondola kwa zipangizo zamakina a CNC ndi ndondomeko yoganizira zambiri komanso yowonjezereka, yomwe imayendetsa ndondomeko yonse yopangira makina opangira makina ndi chitukuko, kupanga ndi kusonkhanitsa, kuika ndi kukonza zolakwika, komanso kugwiritsa ntchito tsiku ndi tsiku ndi kukonza. Pokhapokha pomvetsetsa bwino komanso kudziŵa zambiri ndi luso lamakono lomwe tingathe kusankha mwanzeru chida choyenera kwambiri cha makina a CNC pazochitika zenizeni zopanga, kugwiritsira ntchito bwino momwe zingathere, ndikulowetsa mphamvu zamphamvu ndi chithandizo ku chitukuko cholimba cha makampani opanga zinthu.